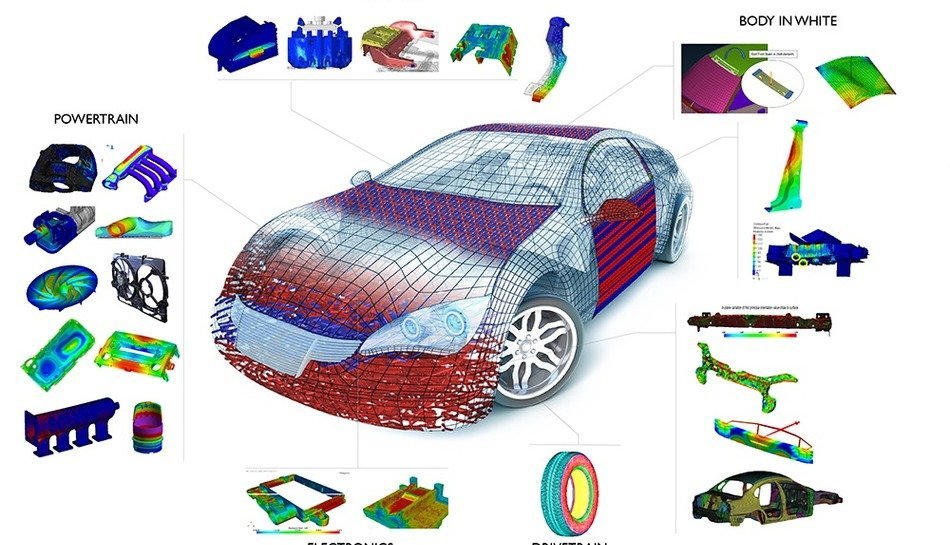

Centroidal solutions perform a variety of durability analysis and our team is engaged in every step of the product development cycle from load case development, analysis, test correlation, and finishing with signoff.

Vehicle:

- Full vehicle durability strength analysis (Non-Linear Analysis):

- Towing Device.

- Luggage tie-down.

- Vehicle jacking.

- Grab strap handle strength.

- Striker attachment stiffness.

- Floor pan concentrated strength.

- Roof & body systems.

- Oil canning, denting.

- A pillar nose deflection.

- luggage compartment floor panel.

- Battery tray static loading.

- Wiper system structural stiffness.

- Drivers integral footrest strength analysis.

- Mounting&Deployment

- Component and subsystem analysis of Steering wheel, bracket, Seatbelt components.

- Mechanical analyses of snap joints during assembly & disassembly of automotive switch components.

- Topology & strength analyses of a gear shift lever, controllers, mirror switch, wipers & keys subjected to misuse loads.

- Mechanical strength optimization analyses to improvement chanical strength by defining rib patterns in several plastic parts such as air bag housing,cover & lever.

- Contact analyses to study the behavior of engage & retention of push button & actuator parts.

- Non linear static analyses of metallic sliding contact blades to satisfy contact Force & strength requirements.

- Durability assessment of Components and sub assemblies of Commercial vehicles.

Closures:

Front and Rear door strength analysis

- Oil canning.

- Denting.

- Static over check.

- Dynamic Overcheck.

- Antitheft, Aero loads.

- Sag & Set.

- Door strength FMVSS 214 Static and Slam load cases.

Durability assessment of Hood

- Torsional stiffness.

- Lateral stiffness.

- vertical bending.

- Deflection due to gravity.

- Front corner stiffness.

- Oil canning.

- denting, Slam.

- Margin and flushness.

- Oil canning.

- Denting & Prop rod loading.

Durability assessment of liftgate:

- Bending rigidity-Cantilever.

- Margin and flushness.

- Wiper stiffness.

- Torsional rigidity.

- Hinge-lateral Stability.

- Hinge-Vertical Stability.

- Oil canning, Denting.

- Slam durability load cases.

Durability assessment of Decklid:

- Lateral Stability.

- Cantilever bending.

- Torsional rigidity.:

- Front corner deflection.

- Open overload.

- Vertical Stability.

- Waterfall deflection.

- Denting.

- Oil canning.

- Slam durability load cases.

Durability assessment of Fender and optimization.

- Instrument panel and glove box strength analysis (Non Linear Analysis):

- Quality feel deflection analysis.

- Strength analysis.

- Thermal analysis.

- Sag Analysis of the Instrument panel & Glove box assembly.

- Durability assessment of console systems (Non Linear Analysis):

- Lateral, Rearward, Vertical downward/upward analysis on armrest.

- ConsoleVerticaldownward, later load cases.

- Rearward & Forward Load test Analysis on End cap Panel of Floor Console assembly

- Durability assessment of door trims (Non Linear Analysis):

- Pull cup analysis, Pull handle Analysis and Door strength Analysis.

- Quality feel deflection, Speaker grill strength, map pocket strength, and Bottle holder strength Analysis.

- Dog house strength, Belt line strength and Door edge deflection analysis.

- Insertion & retention Analysis for different Clips used in Automotive Sub Systems.

- Hard trim strength analysis.

- Optimization & natural Frequency.